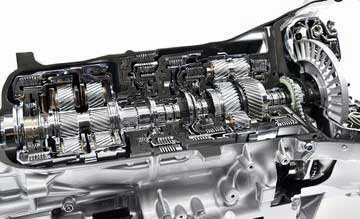

HYDRAMATIC TRANSMISSION

The hydramatic transmissions are also called as the fully automatic transmissions. They have essentially three or four-speed and reverse epicyclic gearboxes with brakes and clutches operated by oil pressure and which are controlled by the joint action of a governor, whose speed is proportional to that of the car and of a valve actuated by the accelerator pedal. Three distinct designs of this fully automatic transmission are currently in use:assisted by springs, which control brake bands on the planetary gear sets and clutches.

|

| hydramatic transmission |

- Controlled-coupling hydramatic transmissions.

- Three-speed hydramatic transmissions.

Construction

The hydramatic drive doesn't have any clutch pedal to engage and disengage the transmission system from the engine. The motion of the vehicle is controlled entirely by accelerator and brake. The hydramatic drive combines a four-speed forward and reverses automatic geared transmission with a fluid flywheel. The geared transmission consists of three sets of constant mesh helical planetary gears placed in series. 2 planetary gear sets provide the 4 forward gear shifts, and the 3rd is used for reverse. The fluid flywheel acts to cushion the impact of the automatic shifts as well as to reduce the torque reactions of the engine. A centrifugal governor of the transmission system selects the proper gear for each speed and throttle position.The change from one gear to another accomplished through hydraulically operated pistons, in the planetary unit. The speed at which the various shifts occur is governed by the throttle position as well as by the centrifugal governor. When the throttle is opened, the gear shifts at higher and top speed is obtained. Driver control is provided by a lever and segment mounted on the steering column beneath the steering wheel which can be adjusted to any one of the four positions-neutral, drive, low and reverse. In the drive position, the transmission shifts automatically for any one of the four forward speeds. The low position is for hill climbing or muddy road.

|

| Hydromatic Transmission |

Gear system. The hydramatic gear system is shown in Figure. It consists of three sets of planetary gears to obtain four forward speeds and the reverse speed. In the front unit, the internal gear is driven by shaft linkage to a torus cover that is bolted to the engine flywheel. The fluid flywheel which is a part of the gear train is also enclosed in this cover. The sun gear is attached to a drum around which a break band is placed for looking at the drum and sun gear when the front unit is used for gear reduction. This setup makes the planet cage as the driven member of the front area when the Sun gear is held stationary. The planet cage is splined to a hollow intermediate shaft, whose front section connects with the driving

member (driving torus) of the fluid flywheel; and whose rear section is splined to the clutch hub of the rear unit. When the planet cage gains power from the internal gear of the front unit, it transmits it forward through the intermediate shaft to the driving torus of the fluid flywheel. There it is transferred to the driven member.

In the rear unit, the internal gear is fastened to a drum-and-break band assembly for locking it when the unit is in reduction. The sun gear is the driving member. It receives its power from the main shaft. The planet cage that splined to the output shaft is the driven member while the internal gear is held stationary.

The reverse unit consists of a sun gear fastened to the internal gear of the rear unit, a planet cage splined to the output shaft and internal gear. The internal gear has external as well as internal teeth and is held stationary when n a pawl or anchor pin engages its external teeth.

The front and rear units contain hydramatically operated multi-disc clutches for locking various gears

together when the units are in direct drive. In the front unit, the clutch can lock the planet cage and the sun gear. when the clutch is applied, the clutch connects the rear section of the intermediate shaft with the internal gear in the rear unit.

Operation Of Different Gear Engagement

First Gear

To apply first gear, both the rear and front units are placed in the reduction by using brake bands to both drums to hold them stationary. With the help of sun gear of the front units locked the power is transmitted from the flywheel to the torus cover and to the planet cage, which revolves around the sun gear(stationary) at a reduced speed. The cage transmits power to the driving torque of the fluid flywheel through the front section of the intermediate shaft. From the driven tours the power is transmitted by the main shaft to the sun gear of the rear unit. The sun gear rotates the planet pinions which further drive the output shaft, The combined gear ratio of the two sets of gears is the product of their gear ratios. The gear ratio in the first speed in the transmission is 3.82:1. when the internal gear and the sun gear of front unit has 67 and 30 teeth and those of rear unit have 67 and 41 teeth respectively. |

| Hydramatic Transmission Or Hydramatic drive |

Second Gear

To obtain a second gear, the front unit is placed in a direct drive by releasing the front band and applying the front clutch. Thus, the power is transmitted from flywheel to the torus cover and then to the locked front unit. There it is transmitted directly by the front section of the intermediate shaft to the fluid flywheel which carries it back to the sun gear of the rear unit through the main shaft. The rear unit carries the entire power to the output shaft. The gear ratio for the second speed is 2.63:1.Third Gear

To obtain third gear, release the clutch and apply the band in the front unit, place it back in reduction, release the band and apply the clutch in the rear unit to convert it to direct drive. The power flow is from the flywheel to the front unit, rear unit and finally to the output shaft. The gear ratio for the 3rd speed is 1.45:1.Fourth Gear

To obtain 4th gear, lock the clutch and release the band in the front unit, shifting it into direct drive and also bearing the rear unit into direct drive. The power flow is done from the flywheel to the locked front unit then to intermediate shaft, rear unit and finally to the output shaft.Reverse Gear

In all the forward speed gears, the reverse unit turns freely and do not transmit power. To obtain reverse gear, place the selector lever in the reverse position, shift the front unit into reduction, Release the clutch and rear band; and engage the anchor pin in the external teeth of the reverse internal gear, to hold the gear stationary. The power will flow from the flywheel to the torus cover, front internal gear, and then to the planet cage, intermediate shaft and then to the fluid flywheel, as in the first gear. From there, it is transmitted to the rear sun gear by the main shaft. When the reverse internal gear is locked, the reverse planet cage cannot turn freely, but hold the rear planet cage to the output shaft. The rear unit planet cage acts here as an idler which causes the rear unit internal gear to turn in a reverse direction. The rear unit internal gear drives reverse sun gear in a reverse direction, causing the reverse planet cage to move the output shaft in reverse. The gear ratio in reverse is 4.30:1.You can watch the video below for knowing the history of Hydramatic drive.

CONTROLLED-COUPLING HYDRAMATIC TRANSMISSION

This type of hydramatic transmission carries so many features of the earlier hydramatic drive, with some major changes. In it, the front planetary unit occupies the space between the torus cover and the fluid coupling but is still driven by the torus cover. The sun gear is linked to a sprag (one-way) clutch and over-running clutch, instead of with a band and servo, to hold its stationary, Another change in the front unit is the use of a liquid coupling in place of hydraulically /operated friction clutch for providing direct drive. The rear unit internal gear can be held by rear sprag clutch or by a servo-operated over-running band to shift the unit into reduction.The rear unit is shifted to direct drive by means of a hydraulically operated friction clutch. A neutral clutch is placed between the outer race of the rear sprag clutch and the transmission case. When it is applied, it allows the rear sprag clutch to hold the rear internal gear. When the neutral clutch is released, it shifts the rear unit into neutral. The gear system is similar to that used in hydramatic drive, however, the methods used to tools shift the gears and locations of gears differ.

|

| Hydramatic drive. |

THREE-SPEED HYDRAMATIC TRANSMISSION

This type of hydramatic transmission offers tree selective forward drive ranges-known as drive left, drive right and low. Reverse and park are the other two positions. In the drive left the range, the transmission starts in first and shifts automatically to second and third.It will not shift above the second unit until a speed limit of 70-82 m/h is reached. In low range, the hydramatic transmission remains in first gear regardless of the amount of throttle opening or vehicle speed.

The three-speed hydramatic transmission consists of three major units

Torque converter fluid coupling

It is composed of the torque multiplier, drive torus, and the driven torus.Front planetary unit

It consists of a sun gear, internal gear, planet gear, and carrier, from the clutch and reverses cone clutch.Rear planetary unit

It consists of a rear sun gear, planet pinions, internal gear, the planet carrier, output shaft, neutral clutch, sprag clutch, and over-running band.Also, Read These Posts

- What is Planetary Gear System?

- What is Fluid Flywheel Or Fluid Drive Or Liquid Coupling?

- What is Torque Converter?

- What is Overdrive Transmission?

- What is an Automatic Transmission?

- What is the Transfer Case? Functions Of Transfer Case.

ConversionConversion EmoticonEmoticon